Full Service Medical Device Manufacturing with Direct Access to Government Procurement

ABOUT MEDISURGE

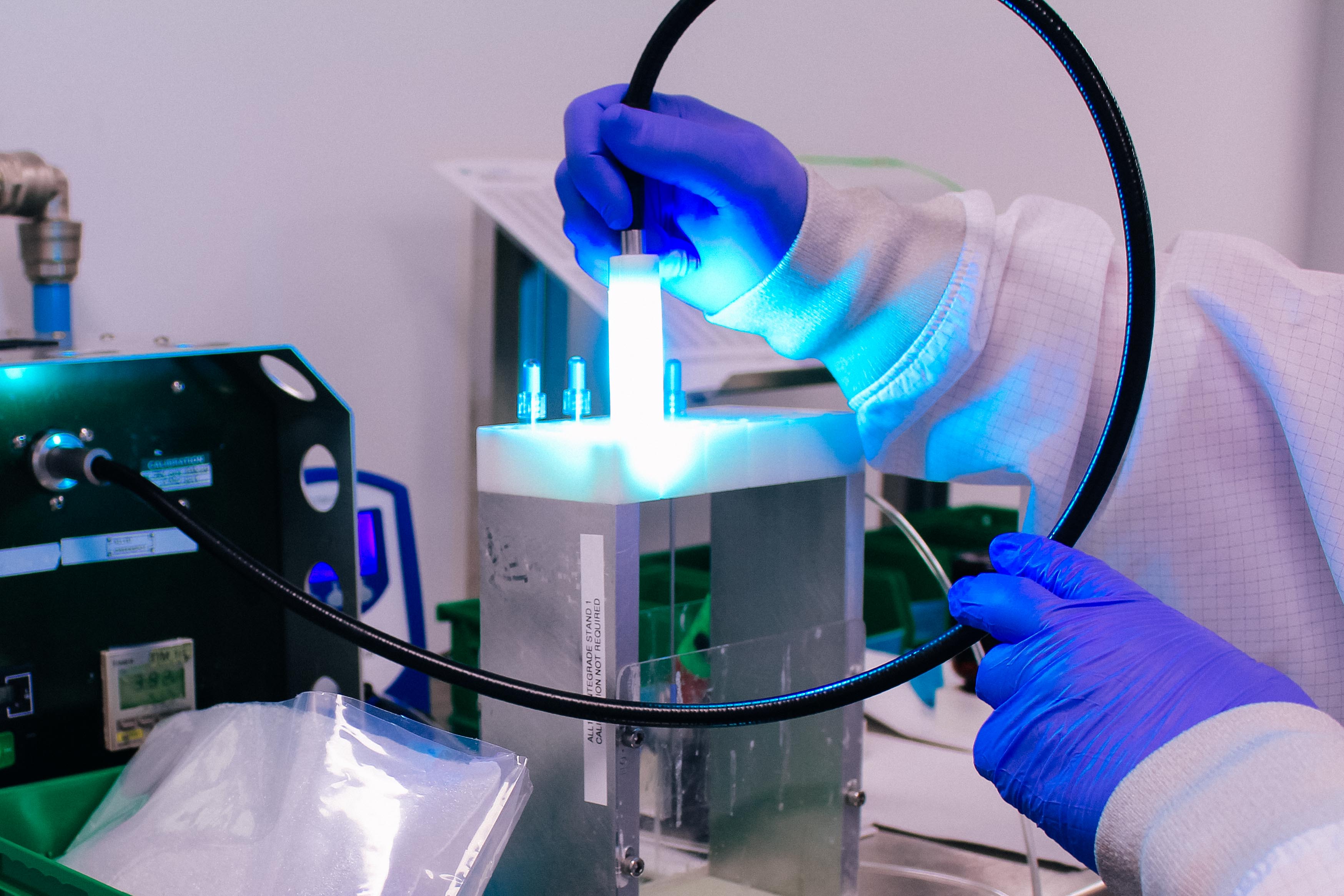

Medisurge is a US-based contract manufacturer of medical devices with unsurpassed quality metrics and continuous improvement to drive cost savings at every step of the process. Our brand new, state-of-the-art facilities are primed for rapid and vast manufacturing expansion. We partner with start-ups and established OEMs to provide all aspects of medical device manufacturing from engineering and manufacturing through sterilization, packaging, warehousing, simplifying supply chain and linking distribution channels.

A significant advantage to our partners is their ability to leverage our direct-to-government distribution through our partner company, Alliant Healthcare Products.

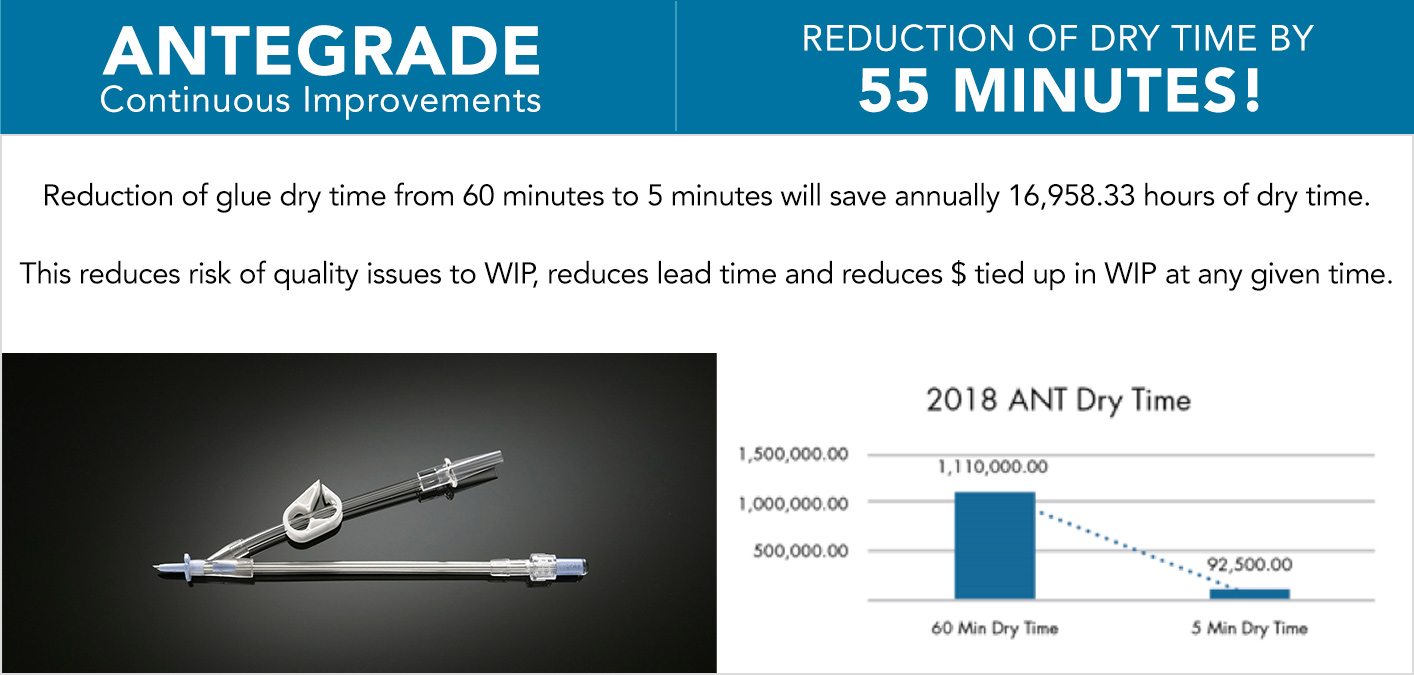

Cost Savings Examples

We implement creative manufacturing solutions and lean production to drive cost savings and expedite lead times from start to finish.

End-to-End Capabilities

From design to distribution, we work with you from the very beginning or can plug in at any stage.

Faster To Market

We help you overcome QA/RA, engineering, supply chain, and manufacturing challenges to get your product to marketing faster.

ALLIANT Family of Companies

We help people live better by manufacturing and distributing innovative medical devices.

Alliant Biotech is an incubator and distributor of new innovative biotechnology products that solve unique medical challenges and protect people from disease.

Medisurge is a full-service contract manufacturer with unmatched quality metrics proven continuous improvement that drives cost savings at every step of the process.

Alliant Healthcare Products is a SVDOSB that specializes in federal government sales, contracting, and distribution, providing substantial pre-established government contracts.